Manufacturing Changes in Pharmaceuticals: What You Need to Know

When a drug maker makes a manufacturing change, a modification in how a medication is produced, including ingredients, facilities, or processes. Also known as production updates, it can happen without public notice—but it might change how your medicine works. These aren’t just behind-the-scenes tweaks. A shift in the factory, supplier, or even the temperature during mixing can affect absorption, side effects, or how long a drug lasts in your body.

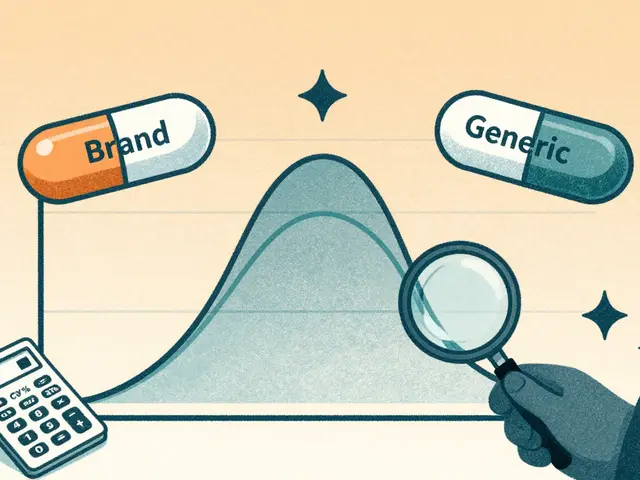

Think about pharmaceutical manufacturing, the process of producing medications at scale under strict regulatory rules. It’s not like baking cookies. One small change—like swapping a filler ingredient or moving production from Ohio to India—can ripple through the whole system. That’s why the FDA tracks these changes closely. But not all changes are flagged for patients. Some are considered "minor," even if they alter how your body handles the drug. And when it comes to generic drug production, the making of non-brand versions that must meet the same standards as the original, the stakes are even higher. Generic makers often compete on price, which can lead to more frequent changes in suppliers or methods. A pill that looks identical might not behave the same way if the manufacturing process shifted last month.

These changes connect directly to drug supply chain, the global network of raw material sources, factories, and distributors that deliver medications to pharmacies. When a single factory in China stops producing a key ingredient, or a hurricane shuts down a U.S. sterile injectable plant, shortages follow. That’s why hospital pharmacies are scrambling. And it’s why some people notice their medication doesn’t work the same—even if the label hasn’t changed. The real difference? The pill was made differently.

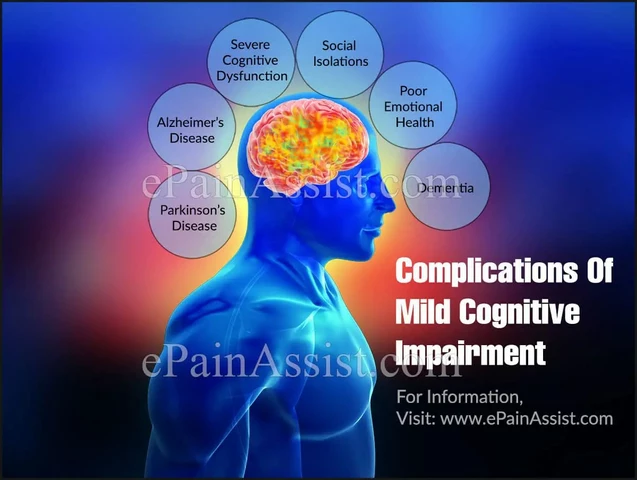

Manufacturing changes also tie into medication safety. A change in tablet coating might slow absorption, causing your blood pressure to spike. A switch in the active ingredient’s crystal form could make your antidepressant less effective. You won’t always be told. But you can learn to spot the signs: new side effects, unexpected dosing issues, or a pill that looks slightly different. If your medication suddenly stops working—or starts causing new problems—ask your pharmacist: "Has the manufacturer changed?" They can check the National Drug Code (NDC) and tell you if a new batch came in.

What you’ll find below are real stories and facts about how these changes impact people. From sterile injectables running low to generics causing confusion, these posts break down what happens when a drug stops being made the same way—and what you can do about it. No fluff. Just what matters for your health.